Accelerating Sustainability for the Future of Mobility through the 2025 Bridgestone World Solar Challenge as a "Mobile Laboratory"

Strengthening Sustainable Initiatives Across the Entire Value Chain—from Raw Materials to Recycling

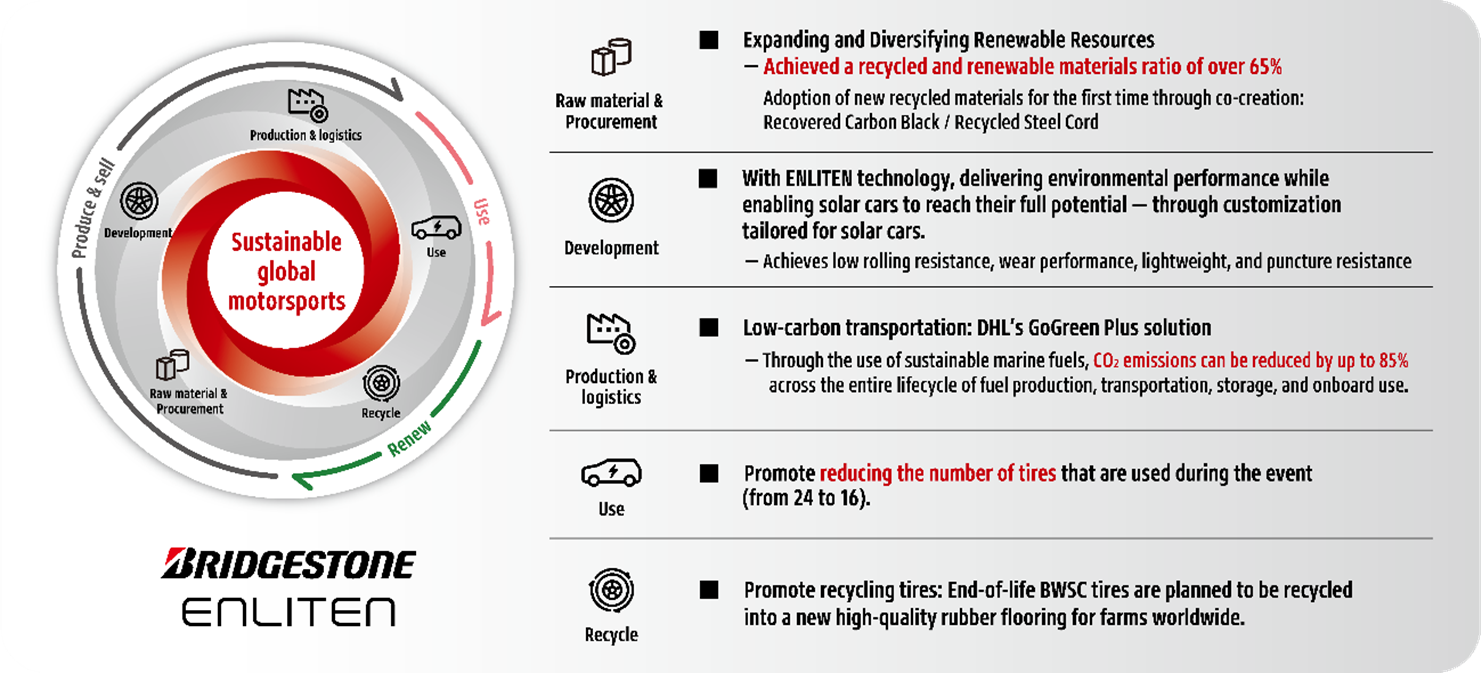

TOKYO (September 2, 2025) - Bridgestone Corporation, the title sponsor of the world’s premier solar car race—the 2025 Bridgestone World Solar Challenge (BWSC) *1, held in Australia from August 24 to 31— supplied tires equipped with ENLITEN® technology*2, featuring over 65% recycled and renewable materials*3. This marks the first time Bridgestone has applied recovered carbon black and recycled steel—developed and produced through co-creation with partners—to BWSC tires. In addition to reducing the number of tires used during the event, implementing low-carbon logistics, and promoting post-use recycling. Bridgestone evolved its sustainability efforts across the entire BWSC tire value chain. Notably, teams equipped with ENLITEN technology tires claimed victory in both the Challenger and Cruiser classes.

【Bridgestone’s Sustainability Initiatives at the BWSC】

1. Raw Materials & Procurement: Increased the ratio of recycled and renewable materials to over 65% through co-creation with partners.

① Recovered Carbon Black:

Through co-creation with ENEOS Corporation, Bridgestone has advanced the development of precise pyrolysis technology to recover materials such as carbon black from end-of-life tires. For the first time, recovered carbon black produced at the Bridgestone Innovation Park (Kodaira City, Tokyo) was adopted for BWSC tires*4*5.

② Recycled Steel:

Bridgestone utilized end-of-life tires collected at the Bridgestone Tire Recycle Center Osaka Corporation to produce recycled steel using electric furnaces at Sanyo Special Steel Co., Ltd. The steel was then rolled and heat-treated by Nippon Steel Corporation into bead wire (a tire reinforcement material), which was adopted for BWSC tires for the first time.

2. Development: Delivered advanced tires equipped with ENLITEN technology

By adopting ENLITEN, Bridgestone’s base technology for product design, the company pursued reduced environmental impact and delivered tires customized to meet the specific performance requirements of solar cars, including low rolling resistance, lightweight construction, and enhanced wear performance. These tires helped maximize vehicle performance under the extreme conditions of the BWSC, contributing to safe and reliable long-distance driving over approximately 3,000 km.

In addition, Bridgestone incorporated Twaron Next®*6, a new aramid material with circular content developed by Teijin Aramid, further advancing the environmental performance of its products and contributing to sustainability.

3. Production & Logistics: Achieving Low-Carbon Transportation

Bridgestone utilized DHL’s GoGreen Plus solution for transporting BWSC tires. By using sustainable marine fuel, the company achieved a reduction of up to 85% in CO₂ emissions across the entire fuel lifecycle—from production, transportation, and storage to onboard usage (Well-to-Wake)—realizing low-carbon transportation.

4. Use: Promoting Reduction in the Number of Tires Used at BWSC

Improved wear resistance of ENLITEN® tires extended driving range, reducing the number of tires supplied per team from 24 to 16.

5. Recycle: Promoting the Recycling of end-of-life Tires

Through co-creation with Australia-based RubberGem, end-of-life tires are planned to be recycled into a new high-quality rubber flooring for farms worldwide.

【Empowering a 3,000 km Endurance Journey Through Innovation】

Teams equipped with Bridgestone’s ENLITEN technology tires won both the Challenger and Cruiser classes. This marks the third consecutive victory in the Challenger class since 2019 and the fourth consecutive win in the Cruiser class since 2017 for Bridgestone-equipped teams. Through its support of the BWSC, Bridgestone is committed to being essential to the future of mobility by accelerating innovation for a sustainable mobility society and nurturing the next generation of engineers.

Comments from Winning Teams and Bridgestone Executive:

Challenger Class Winner : Mr. Elias Wawoe - Brunel Solar Team (Delft University of Technology)

“The last time we won the BWSC was eight years ago, and since then, we have been working toward becoming world champion again. The Bridgestone tires performed exceptionally well, especially in terms of wear resistance, supporting our journey to victory. The BWSC tires were a great example of accelerating sustainability in the tires; through the event, these efforts were showcased. What we try to show is the combination of innovation and striving for a sustainable future.”

Cruiser Class Winner : Mr. Kelvin To – VTC Solar Car Team (Hong Kong Institute of Vocational Education)

“We have been working on the BWSC for more than ten years, and winning this competition means a lot to us. Our students from engineering and design put classroom skills into the real-life 3,000km project of the BWSC. We take part to showcase the latest technology in renewable energy and be part of the force that drives into a sustainable future. Bridgestone tires were very reliable—no punctures over sand, pebbles, and potholes—and they helped us save a lot of energy throughout the trip.”

Bridgestone E8 Commitment Award Winner : Mr. Joel Pitts - Iron Lions Solar Car Team (Greenville High School)

“We are truly humbled to receive the Bridgestone E8 Commitment Award. Our students and teachers set a goal to build a world class solar car that would qualify and compete in the Challenger Class. This recognition affirms our commitment and drive to become world-class solar teams.”

Hiroshi Imai, Vice President and Senior Officer, responsible for Global Motorsports, Bridgestone Corporation:

“I would like to express my heartfelt gratitude to all the teams, team staff, families, organizers, and the many volunteers who contributed to the success of the BWSC. It was truly inspiring to witness the passion of everyone involved come together to create such a remarkable event. We are proud that our tires equipped with ENLITEN technology supported not only the winning teams but many others throughout the challenge. As both a tire supplier and the title sponsor, Bridgestone remains committed to supporting the realization of sustainable mobility and the development of future engineers and leaders through the BWSC.

With passion, we continue to challenge the limits together with the teams and aim to apply the innovations born in this ‘mobile laboratory’ to future sustainable global motorsports activities.”

Challenger Class winning team

“Brunel Solar Team”

Cruiser Class winning team

“VTC Solar Car Team”

*1 Bridgestone World Solar Challenge official website: https://www.bridgestone.com/bwsc/

Organizer Website: https://worldsolarchallenge.org/

*2 ENLITEN is a technology that evolves environmental performance, expands basic performance,

and elevates all conventional performances in tires. It also pursues "ultimate customization" to sharpen the edge in tire performance which not only meets the apparent needs and potential wants of the markets and customers, but also further inspires markets and customers by creating new value that they may not have imagined, according to the characteristics of diverse vehicles and usage conditions.

*3 Recycled material has been reprocessed from recovered [reclaimed] material by means of a

manufacturing process and made into a final product or into a component for incorporation into goods or services. Renewable material is composed of biomass from a living source and can be continually replenished. The material shall come from sources that are replenished at a rate equal to or greater than the rate of depletion. (These definitions are based on ISO 14021: 2016)

*4 2023/06/08 Bridgestone Commences Pyrolysis Test of Used Tire Recycling

*5 This achievement described in text is attributed to a grant project funded by the New Energy and Industrial Technology Development Organization (NEDO) in Japan.

*6 Twaron Next® is a registered trademark of Teijin Aramid.

About Bridgestone Corporation:

Bridgestone is a global leader in tires and rubber building on its expertise to provide solutions for safe and sustainable mobility. Headquartered in Tokyo, the company employs approximately 121,000 people globally and conducts business in more than 150 countries and territories worldwide. Bridgestone offers a diverse product portfolio of premium tires and advanced solutions backed by innovative technologies, improving the way people around the world move, live, work and play.